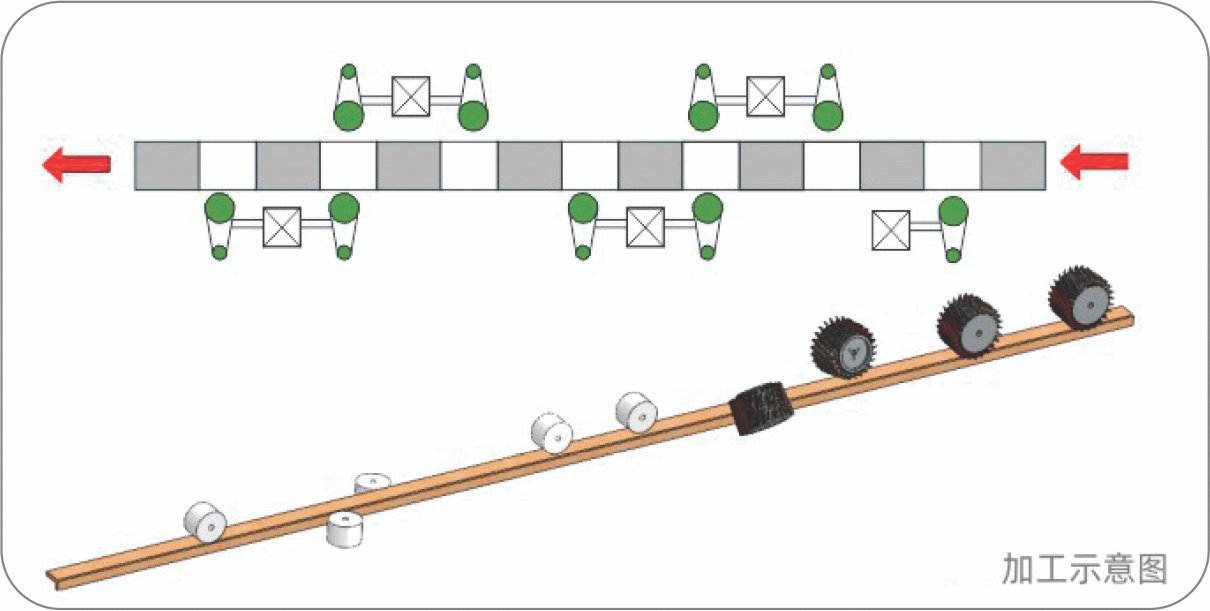

1. Adopting a modular design, the multi head independently adjustable sand head is flexible in configuration, and the configuration scheme can be selected according to the process characteristics of different materials, such as six head, seven head, nine head, and twelve head, etc. It has wide adaptability and is easy to combine into a continuous processing production line.

2. The sand head design has strong versatility and can adapt to various irregular surfaces for sanding, polishing, and polishing. According to different materials such as solid wood, density board, veneer board, and primer board, different levels of grinding heads can be selected for polishing, rough, and fine sanding. At the same time, dual-use sand frames and octagonal sand can be used to make the surface of the wood line more delicate and smooth, meeting customers’ different requirements for surface processing of the line.

1. Grinding head: It can use a molded grinding wheel to grind complex shapes, and is equipped with an automatic compensation device to ensure that the grinding wheel can continue to grind during grinding

Ensure grinding accuracy.

Dual purpose sanding rack: It can be used for both flat sanding and irregular sanding, and is equipped with an automatic compensation device;

3. The feeding of each section is synchronized, with mechanical continuously variable speed, convenient speed regulation, and high conveying force. The rubber feeding belt is durable and has a uniform speed, suitable for sanding various materials and primers.

4. Any grinding head or dual-purpose sand frame can achieve 360 ° angle adjustment, which is more suitable for production needs.

5. The material pressing device adopts point pressing and spring loading, suitable for irregular surface workpieces, and can be pressed reliably without damaging the workpiece. It also includes a short material bridge device, which can pass short materials (450mm).

6. Microcomputer control, fully automatic sand roller action, TP human-machine control panel, simple and beautiful, easy and reliable operation, high degree of automation, low failure rate. Automatically accumulate production statistics, making production management more convenient.

7. We can also customize special models and design and manufacture wood processing production lines according to customer needs.

Reviews

There are no reviews yet.